Voltage: 310V Fan Coil BLDC Motor

Output Power: 20W-200w

Run Speed: 8 Poles (500-1500RPM)

Number of Speeds: various

Shaft Length: as your need

Shaft Diameter: as your need

Shaft Rotation: CW / CCW

Shaft details: Single shaft / Double shafted

Mounting Centres: 95/100/105mm

Base Included: 95mm shaft centre height

Body Type: Totally Enclosed /Ventilated

Example applications: Fan convector, fan coil unit, warm air heater, comfort cooling, AHU (air handling units), warm air door curtains, fan decks, air conditioning and other HVAC equipment.

EC motor, bldc motor

bldc fan motor Phase: 1

Thermal Protection: Automatic

ec brushless motor Dia: 160mm

bldc motor speed control: variable

Voltage of ec motor control: 0-10V

with china brushless bldc motor driver

Maximum Ambient Temperature: 70° C

Insulation Class ofbrushless ec motor: B/F

Permanent Split Capacitor (PSC) china ec fan motor

EC motor, bldc motor

bldc fan motor Phase: 1

Thermal Protection: Automatic

ec brushless motor Dia: 160mm

bldc motor speed control: variable

Voltage of ec motor control: 0-10V

with china brushless bldc motor driver

Maximum Ambient Temperature: 70° C

Insulation Class ofbrushless ec motor: B/F

Permanent Split Capacitor (PSC) china ec fan motor

Voltage: 310-360V BLDC Motor for fan coil

Output Power: 20W-200w

Run Speed: 8 Poles (500-1500RPM)

Number of Speeds: various

Shaft Length: as your need

Shaft Diameter: as your need

Shaft Rotation: CW / CCW

Shaft details: Single shaft / Double shafted

Mounting Centres: 95/100/105mm

Base Included: Yes, 95mm shaft centre height

Body Type: Totally Enclosed /Ventilated

Example applications: Fan convector, fan coil unit, warm air heater, comfort cooling, AHU (air handling units), warm air door curtains, fan decks, air conditioning and other HVAC equipment.

Voltage: 310-360V BLDC Motor for fan coil

Output Power: 20W-200w

Run Speed: 8 Poles (500-1500RPM)

Number of Speeds: various

Shaft Length: as your need

Shaft Diameter: as your need

Shaft Rotation: CW / CCW

Shaft details: Single shaft / Double shafted

Mounting Centres: 95/100/105mm

Base Included: Yes, 95mm shaft centre height

Body Type: Totally Enclosed /Ventilated

Example applications: Fan convector, fan coil unit, warm air heater, comfort cooling, AHU (air handling units), warm air door curtains, fan decks, air conditioning and other HVAC equipment.

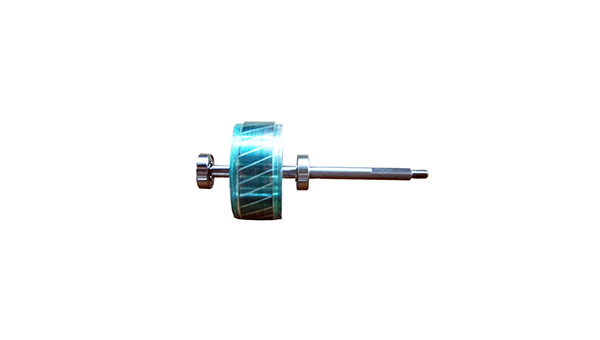

DC MOTOR is a motor converts supplied electrical energy into mechanical energy. Various types of motors are in common use. Brushless DC motor (BLDC) ,also known as an electronically commutated motor (ECM or EC motor) features high efficiency and excellent controllability. The BLDC motor has power-saving advantages relative to other motor types. As professional ec motor manufactrurers our brushless motor main uses in air conditioner or fan coil unit or centrifugal fan.

BYJ Stepper Motor from Tingertech is one of the most commonly used step motor in DVD drive, Motion camera, air conditioners, dehumidifiers, circulating fans, smart toilets, tea bar machines, surveillance cameras, stage lighting, purifiers and other household equipment and more similar devices.

BYJ Stepper Motor from Tingertech is one of the most commonly used step motor in DVD drive, Motion camera, air conditioners, dehumidifiers, circulating fans, smart toilets, tea bar machines, surveillance cameras, stage lighting, purifiers and other household equipment and more similar devices.

BYJ Stepper Motor from Tingertech is one of the most commonly used step motor in DVD drive, Motion camera, air conditioners, dehumidifiers, circulating fans, smart toilets, tea bar machines, surveillance cameras, stage lighting, purifiers and other household equipment and more similar devices.

BYJ Stepper Motor from Tingertech is one of the most commonly used step motor in DVD drive, Motion camera, air conditioners, dehumidifiers, circulating fans, smart toilets, tea bar machines, surveillance cameras, stage lighting, purifiers and other household equipment and more similar devices.

BYJ Stepper Motor from Tingertech is one of the most commonly used step motor in DVD drive, Motion camera, air conditioners, dehumidifiers, circulating fans, smart toilets, tea bar machines, surveillance cameras, stage lighting, purifiers and other household equipment and more similar devices.

BYJ Stepper Motor from Tingertech is one of the most commonly used step motor in DVD drive, Motion camera, air conditioners, dehumidifiers, circulating fans, smart toilets, tea bar machines, surveillance cameras, stage lighting, purifiers and other household equipment and more similar devices.

BYJ Stepper Motor from Tingertech is one of the most commonly used step motor in DVD drive, Motion camera, air conditioners, dehumidifiers, circulating fans, smart toilets, tea bar machines, surveillance cameras, stage lighting, purifiers and other household equipment and more similar devices.