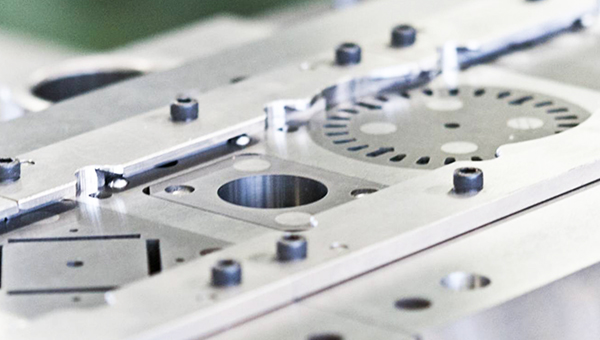

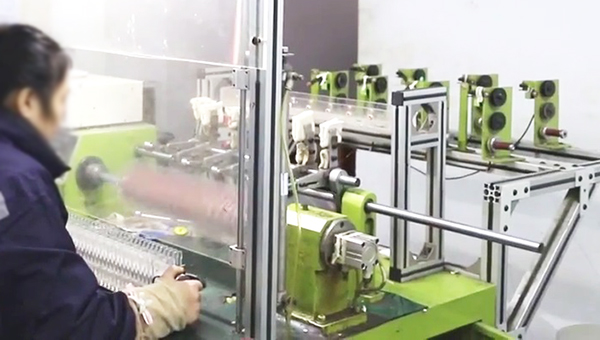

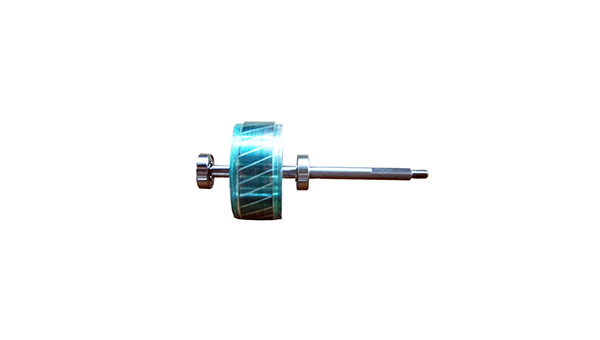

Motor assembly includes assembling stator assembly, rotor assembly and end cover assembly with front cover. Fan motor testing in china ac motor manufacturer, Tingertech, covers the whole areas from stator insulation test, electronic integrated test bench for winding inserting, motor integrated test bench, motor performance test, noise test and appearance detection through to dynamometer for high performance electric motor testing, by which fan motor supplier,

Tingertech, can ensure to offer you

fan motor of competitive higher quality at reasonable

ac fan motor price.