The TGB Series centrifugal fan is kind of air-conditioning fan. The centrifugal fan impeller is driven by three phases external motor. It was developed by using high technology and with low noise and compact structure. It was specially designed for the air-conditioning. The flow rate and total pressure range of this series centrifugal fan are from 1000m /h to 20000m /h and 200Pa to 850Pa. It is the ideal equipment for the air-conditioning and other kind of fan system.

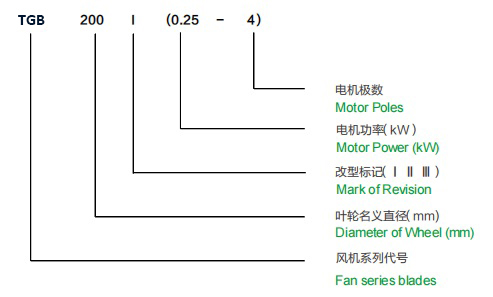

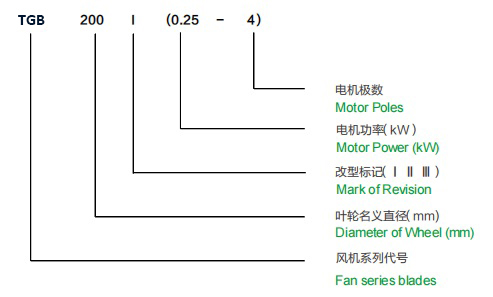

Nomenclature of Centrifugal Fan

Features of Centrifugal Blowers

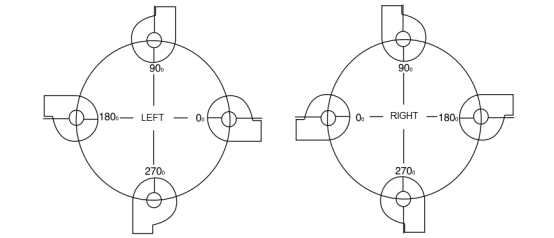

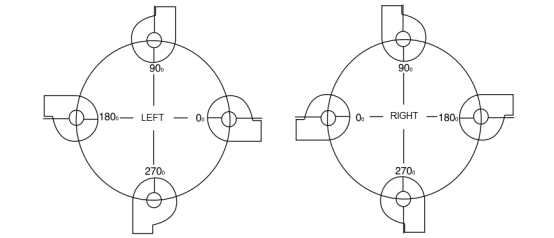

1. Rotation Direction

TGB series Centrifugal fan have two direction of rotations, left-hand rotation (LG) and right-hand rotation (RD); Viewing from drive side, if the centrifugal fan impeller rotates clockwise, it is left hand (LG) rotation. If the centrifugal fan blade rotates counter clockwise, it is right-hand (RD).

2. Discharge Direction

According to below fig, TGB Series centrifugal fans can be made in four air-outlet directions:0°, 90°, 180°, and 270°.

Centrifugal Fan Design

Centrifugal fan of TGB series consist of centrifugal fan housing, centrifugal fan impellers, centrifugal fan baseplate(frame), motor, shaft sleeve and air outlet flange.

1. Centrifugal Fan Housing

The centrifugal fan housing is made of hot galvanized steel sheet. The side plates of centrifugal fan include inlets cones that are designed with the best aerodynamics for inlet condition. The scroll of centrifugal fan blower is fixed to the side plates by spot welding. On the side of the centrifugal fan scroll, there is a series of holes drilled in advance for riveting nuts to carry out installation according to air outlet direction needed by the customer.

2. Centrifugal Fan Impeller

Forward curved centrifugal fan impeller is constructed of high-grade hot galvanized steel sheet with the advanced aerodynamics profile to achieve the highest efficiency and the lowest noise level. The centrifugal fan blade is fixed on the center plate and on the end ring with riveting grip pres. The centrifugal fan wheel is constructed with maximum strength that endures the continuous operation with maximum power. All centrifugal fan impellers are balanced to National Standard even higher for wheel balancing.

3.Centrifugal Fan Frame

TGB Series centrifugal fan baseplate is made of high quality hot galvanizing steel sheet, and the unique process of strengthening ensures the sufficient strength. The direction of centrifugal fan baseplate installation can be carried out according to the different requirements of customers, Over 315 centrifugal fan frame is made of angle steel and flat steel. On four sides of the frame, there are holes drilled for installation to meet customers' requirements in different installation directions of centrifugal fan blowers.

4. Centrifugal Fan Motor

The centrifugal fan motor used in TGB series centrifugal fans are low noise three phases asynchronous ac fan motors with external rotors. The centrifugal fan impeller is installed on the external casing of the ac fan motor. The motor rotation speed can be changed by using provided with three-phase voltage regular, silicon controlled, voltage regulator, frequency converter and etc. to satisfy the changeable load in the system.

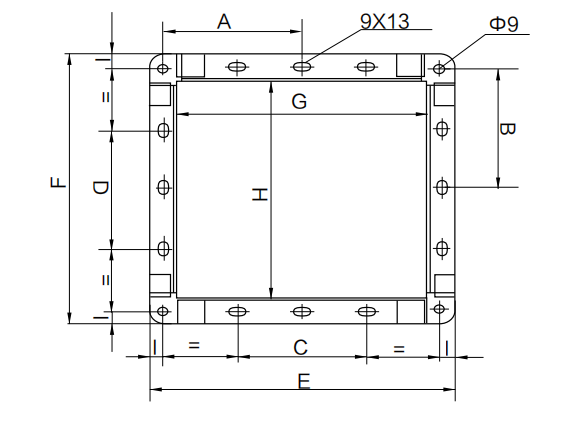

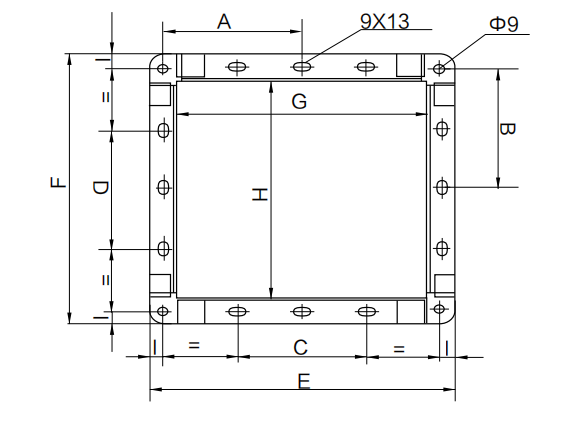

5. Centrifugal Fan Flange

The centrifugal fan flange is made of galvanized steel. The connections of the flange components to the centrifugal fan scroll are made using non-welding process. This maintains a good flange appearance while also providing sufficient strength and rigidity. The dimensions and type of flange are shown below.

| TYPE | A | B | C | D | E | F | G | H | I |

| 200 Ⅰ | 122.5

| 119.5 | - | - | 265 | 259 | 225 | 219 | 10 |

| 200 Ⅱ | 160 | 125 | - | - | 340 | 270 | 300 | 230 | 10 |

| 225 Ⅰ | 139 | 133 | - | - | 298 | 286 | 258 | 246 | 10 |

| 225 Ⅱ | 154 | 133 | - | - | 328 | 286 | 288

| 246 | 10 |

| 225 Ⅲ | 160 | 146.5 | - | - | 340 | 313 | 300 | 273 | 10 |

| 250 Ⅰ | 150.5 | 146.5 | - | - | 321 | 313 | 281 | 273 | 10 |

| 250 Ⅱ | 160 | 146 | - | - | 340 | 312 | 300 | 272 | 10 |

| 280 Ⅰ | 160 | 162.5 | - | - | 340 | 345 | 300 | 305 | 10 |

| 280 Ⅱ | 188 | 162.5 | - | - | 396 | 345 | 356 | 305 | 10 |

| 315 Ⅰ | - | - | 140 | 140 | 394 | 394 | 338 | 338 | 13 |

| 315 Ⅱ | - | - | 140 | 140 | 456 | 394 | 400 | 338 | 13 |

| 355 Ⅰ | - | - | 140 | 140 | 431 | 431 | 375 | 375 | 13 |

| 355 Ⅱ | - | - | 140 | 140 | 487 | 431 | 431 | 375 | 13 |

| 400 Ⅰ | - | - | 140 | 140 | 475 | 475 | 419 | 419 | 13 |

| 400 Ⅱ | - | - | 140 | 140 | 516 | 475

| 460 | 419 | 13 |

| 450 Ⅰ | - | - | 170 | 170 | 525 | 525 | 469 | 469 | 13 |

| 450 Ⅱ | - | - | 170 | 170 | 586 | 525 | 530 | 469 | 13 |

| 500 Ⅰ | - | - | 170 | 170 | 562 | 562 | 506 | 506 | 13 |

| 500 Ⅱ | - | - | 170 | 170 | 656 | 562 | 600 | 506 | 13 |

Note: the size unit of centrifugal fan in the form and overall size are mm.

Instructions of Centrifugal Blower Fans

1) The rated centrifugal fan motor power, one of centrifugal fan parts, as calculated herein might not be sufficient to drive the centrifugal fan with an unrestricted discharge flow. Operating the centrifugal blower fan with an unrestricted discharge outlet will result in flow rate that exceeds the specified fan capabilities. Such operation will quickly burn the blower motor and damage the centrifugal fan. Great care must be taken in operating the centrifual fan to make sure that the maximum rated flows, as provided on the centrifugal fan performance charts in this centrifugal fan description, are not exceeded.

2) The centrifugal duct fan performance is tested under the motor rated speed, we can meet the actual requirement of the user by changing the motor speed.

3) Special care of centrifugal fan / inch blower should be taken during transportation, load and unload.The centrifugal blower fan is limited for use in areas where air substances are non-corrosive, non-toxics and non-erosive.

4) Following the installation, the centrifugal fan impeller should be turned by hand or with the use of a wrench to make sure that it turns freely without colliding with other centrifugal fan parts. Once all this is done, the centrifugal blower fan can be commissioned normally.

5) A flexible connector of centrifugal blower fan should be used between the fan out let flange and its mating ductwork. The flex connector should not be over-stretched.

6) The inside of the scroll and casing need to be checked to make sure that there are no foreign objects inside the centrifugal fan housing, such as tools or loose parts.

7) The rotational directions of the centrifugal box fan condenser motor and centrifugal fan wheel should be checked to ensure that they are in compliance with the specification and purchase orders.

8) During ordering it is necessary to state the centrifugal fan types, centrifugal fan motor type, centrifugal fan airflow, centrifugal fan air pressure and other centrifugal fan parameters.

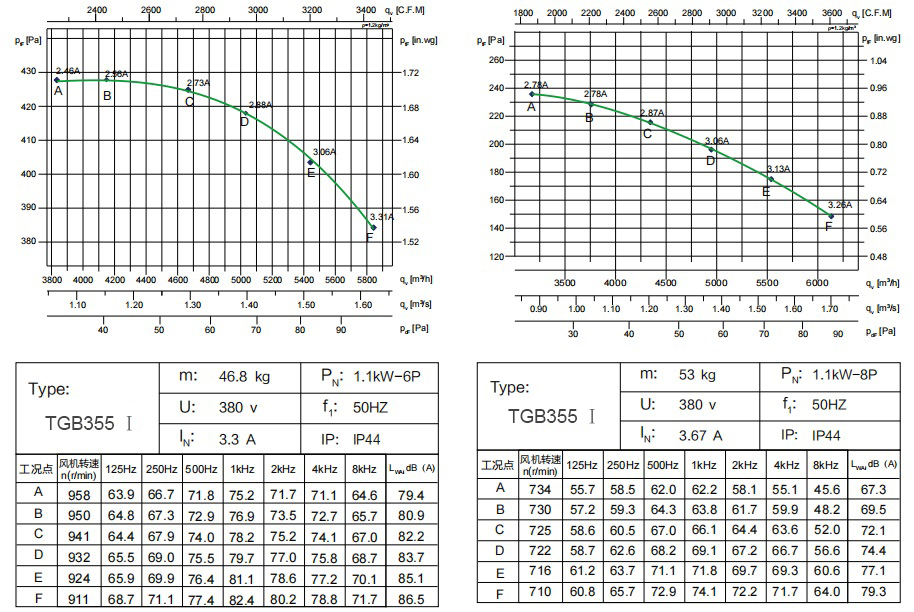

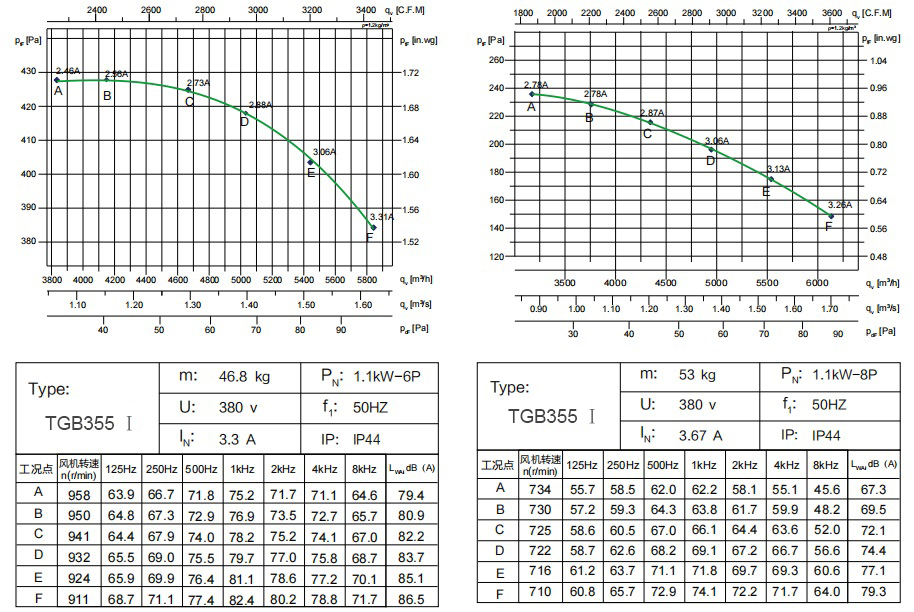

Centrifugal Fan Curve & Centrifugal Fan Diagram

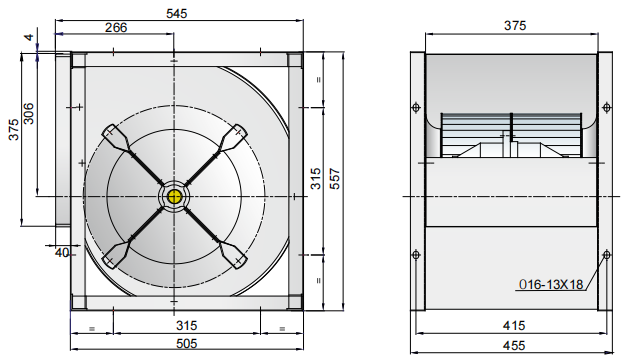

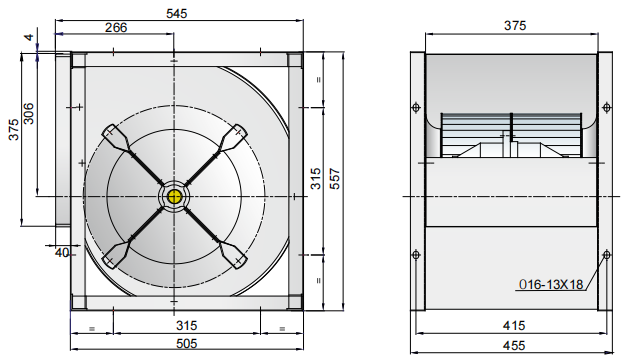

Overall Size of Centrifugal Blower Fan

Contact your China Centrifugal Fan Manufacturer for Centrifugal Fan Catalogue and Get Centrifugal Blower Cost.