Cooler Motor Models

| Model | Voltage (V) | Frequency (Hz) | Output (W) | Speed (RPM) | Capacitor (μF) | Rotation |

| YDK140-150-6T5 | 220-240 | 50 | 1/5HP | 850/3 SPD | 10 | CCW |

| YDK160-185-4A | 115/127 | 50/60 | 1/4HP | 1425/1725 | 10 | CW-SE |

| YDK160-185-4A2 | 220/230 | 50/60 | 1/4HP | 1425/1725 | 10 | CW-SE |

| YDK160-245-4A | 115/127 | 50/60 | 1/3HP | 1425/1725 | 10 | CW-SE |

| YDK160-245-4A2 | 220/230 | 50/60 | 1/3HP | 1425/1725 | 15 | CW-SE |

| YDK160-375-4A | 115/127 | 50/60 | 1/2HP | 1425/1725 | 15 | CW-SE |

| YDK160-375-4A2 | 220/230 | 50/60 | 1/2HP | 1425/1725 | 20 | CW-SE |

| YDK160-550-4A | 115/127 | 50/60 | 3/4HP | 1425/1725 | 20 | CW-SE |

| YDK160-550-4A2 | 220/230 | 50/60 | 3/4HP | 1425/1725 | 20 | CW-SE |

| YDK160-735-4A | 115/127 | 50/60 | 1HP | 1425/1725 | 30 | CW-SE |

| YDK160-735-4A2 | 220/230 | 50/60 | 1HP | 1425/1725 | 30 | CW-SE |

| YDK120-120-4 | 220/240 | 50/60 | 120 | 1350 | 5 | CW-SE |

| YDK139-150-6 | 208-230 | 50/60 | 150 | 930 | 10 | CW-SE |

| YDK139-200-4 | 208-230 | 50/60 | 200 | 1180 | 10 | CW-SE |

| YDK139-350-4 | 208-230 | 50/60 | 350 | 930 | 12 | CW-SE |

| YSK139-350-4 | 208-230 | 50/60 | 350 | 1200 | 10 | CW-SE |

| YDK139-100-10 | 208-230 | 50/60 | 100 | 520 | 6 | CW-SE |

| YDK139-150-4 | 208-230 | 50/60 | 100 | 1100 | 6 | CW-SE |

Air Cooler Motor Features

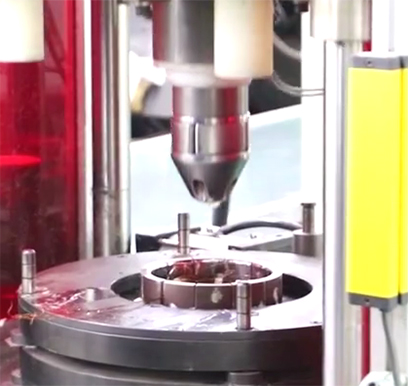

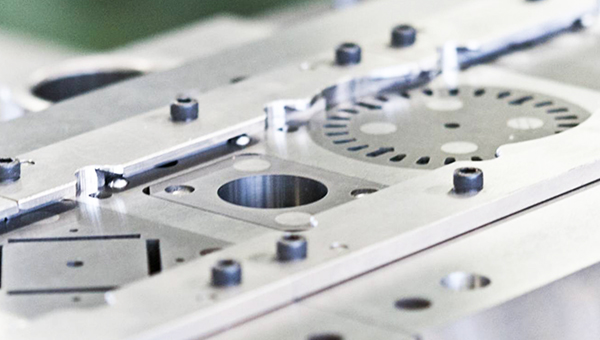

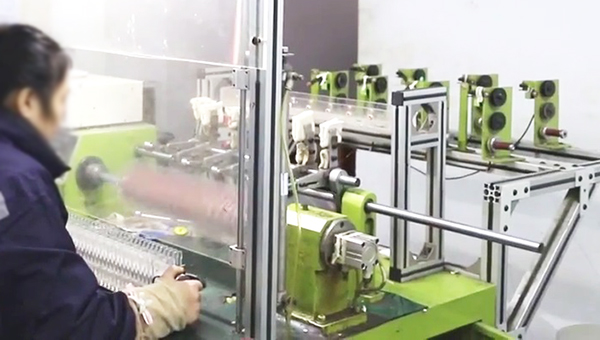

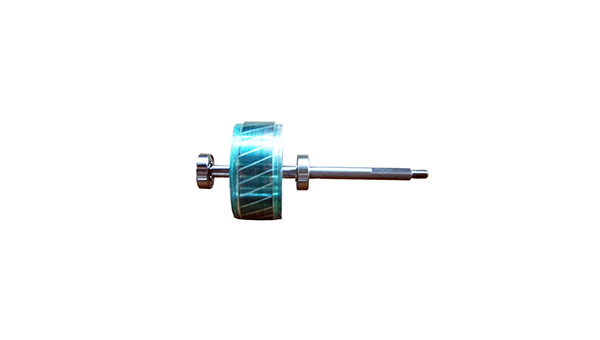

1. Tingtech's single phase capacitor start desert cooler motors, swamp cooler fan motors, evaporative cooler motors and other air cooler fan motors are with steel housing, designed for cooling system, evaporative air cooler etc, suit for hot weather environments.

2. Stable quality cooler motor wiring is with excellent insulation and heat transmission properties.

3. Nice appearance, high starting torque, low starting current, smooth turning, low temperature rise, low vibration, low noise and great overload performance.

4. Saving energy cooler fan motors, higher efficiency cooler motors.

5. Long life evaporative cooler motor which quipped with overheating protection, good Protection against Humidity.

6. Cooler Fan Motor models are with power of 25W, 30W, 45W, 60W, 80W,100W, 120W, 150W, 180W, 200W, 250W, 300W, 750W, 1100W & 1/5HP, 1/3HP, 1/2HP, 1/5HP, 3/4HP, 1HP.

7. Special swamp cooler motors can be designed according to customer's requirement.

8. Our evaporative cooler fan motors are wildly used in market of Saudi Arabia, UAE, Dubai, Bahrain, Iraq, Sudan, Iran, Kuwait, Jordan, Oman, Yemen, etc.