AC condenser fan motors are very complex - there are many different horsepower ratings, speeds, sizes...

Here I will explain how to determine if your AC condenser fan motor is bad and how to test your AC condenser fan motor and will also discuss everything you need to know when shopping for a replacement AC condenser fan motor.

How do you know when your AC condenser fan motor is bad?

Here are a few signs that your AC condenser fan motor is bad:

The condenser fan will not turn on even though the compressor is running.

The condenser fan is on but spinning slowly.

Condenser fan motor humming or other strange noises when turned on.

Your condenser fan motor emits a burning smell.

How to Troubleshoot an AC Condenser Fan Motor

If you suspect your AC condenser fan motor is bad, you can do some tests.

Here are the tests required to test the AC condenser fan motor:

Check motor bearings and shafts

Test the motor windings for open or short circuits

Test the motor winding for short circuit to ground

Test motor capacitor

a. Check motor bearings and shafts

The first thing to check for an AC condenser fan motor is its bearings and shaft.

Bearings are responsible for assisting the motor to rotate. They support the rotor inside the motor, allowing it to spin freely.

Some condenser fan motors require regular oil filling to function properly. If not lubricated, the motor's bearings may wear out or be damaged.

If the bearings are damaged, the motor will not be able to spin freely.

An easy way to test the bearing is to rotate the motor shaft by hand. The shaft should turn freely.

If you feel any friction or inconsistent rotation, the motor's bearings are damaged.

If the motor bearing is damaged, the motor needs to be replaced.

b. Test the motor windings

Testing the windings of the condenser fan motor is a simple test that can be used to determine if the motor is bad.

In order to perform the following tests, you will need a multimeter. Switch the multimeter to its resistance (ohm or Ω) setting.

To test the PSC condenser fan motor, follow these steps:

1. Turn off the power to the AC capacitor.

2. Disconnect the motor from the capacitor and contactor. Keep track of the wire connections as you will need to rewire them after completing the test.

3. Take the resistance reading between each pair of wires.

For example, if you have purple, brown, and black wires, get the following resistance readings:

1. Purple to black

2. Purple to brown

3. Black to Brown

NOTE: If your PSC motor has 4 wires, then you can ignore the 4th wire (usually brown with white stripes).

1. Add two smaller resistance readings.

1. If you add the two smaller resistance readings to the larger resistance reading, there is no problem with the motor.

2. If the two smaller resistance readings do not add to the larger resistance reading, the motor is bad.

For example, if your three resistors are 20Ω, 30Ω, and 50Ω, the motor is good, because 20+30=50.

If any resistance reads OL (open line) or short circuit (about 0Ω or 1Ω), the motor is bad.

c. Test the motor for a short circuit

Another test you can do with the condenser fan motor is to test it for a short to ground.

When the motor windings are shorted to ground, the motor will not work.

To test your AC condenser fan motor for a short to ground, follow below steps:

1. Turn off the power to the AC capacitor.

2. Disconnect the motor from the capacitor and contactor. Keep track of the wire connections as you will need to rewire them after completing the test.

3. Take the resistance reading between each wire and the motor housing one at a time.

4. If the resistance of any motor wires is less than 100 megohms (MΩ), the motor is shorted to ground and needs to be replaced.

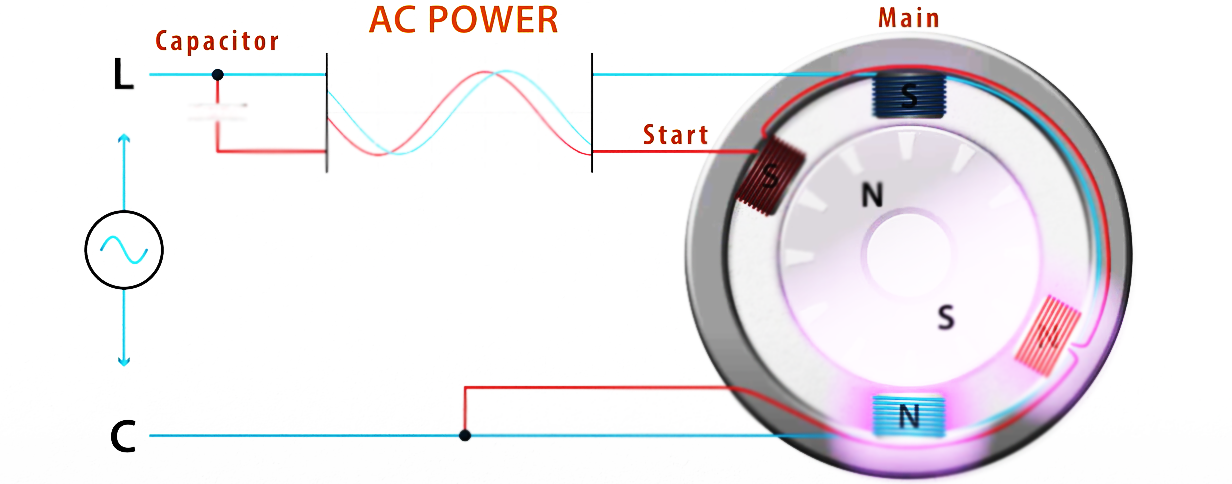

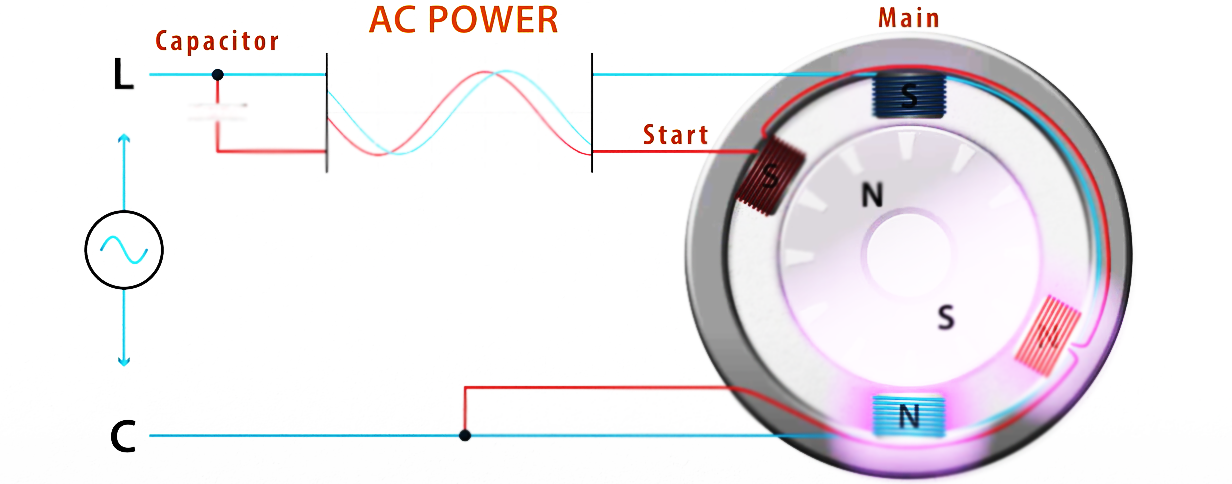

d. Test Motor Capacitor

Sometimes there may not be any problems with the motor itself. The problem might be the capacitors of the motor.

If the capacitor of the motor is bad, then the motor will not run. In rare cases, the motor may run without the capacitor, but the motor will eventually overheat and be damaged.

Most fan motors will run with undersized capacitors, but the life of the motor will be shortened. This is because capacitors that are too small or too large can cause the condenser fan motor to overheat. Therefore, it is very important to use capacitors with the correct rating.

If you have a multimeter with a capacitance tester, then you can test your capacitance to confirm it is working properly.

To test the capacitors of the motor, follow below steps:

1. Turn off the power to the AC capacitor.

2. Disconnect the wires connected to the capacitors. Remember where the wires are attached - you'll have to put them back when you're done.

3. Use a screwdriver to short the terminals to discharge the capacitor.

4. Connect the multimeter leads to the "C" and "FAN" terminals on the capacitor.

5. Turn the multimeter to the capacitance setting (µF, MFD or capacitor symbol - see below).

6. Take the capacitance reading. It will be measured in microfarads (µF).

7. Compare the multimeter's capacitance reading to the capacitor's specification. The capacitance reading should be within the capacitor's specification.

For example, a capacitor rated at 5μF ± 6% should measure between 4.7 and 5.3 μF. If the capacitance is not measured within specifications, the capacitor is bad.

9 Things to Know When Buying a Replacement AC Condenser Fan Motor

When shopping for a replacement AC condenser fan motor, you will need some key information.

I'll go over the different specs you need to know to get the right AC condenser fan motor below:

1. Horsepower

2. Amperage

3.RPM

4. Voltage

5. Shaft size

6. Frame size

7. Speeds

8. Direction of rotation

9. Capacitors

1. horsepower

Horsepower is a measure of motor power. The more horsepower a motor has, the more work it can perform.

Does horsepower have an effect on the condenser fan motor?

Yes, the power of the AC condenser fan motor is important. The new motor needs to have the same horsepower as the motor you are replacing.

If the new motor has more horsepower than the old motor, then the new motor will be underloaded.

If the new motor has less horsepower than the old motor, the new motor is overloaded.

Motor underload or overload can cause the motor to overheat and cause an electrical trip.

Some say there is no harm in using a higher horsepower motor than the one you are replacing.

For example, replace a ⅕ HP motor with a ¼ HP motor. While it probably won't do much damage, I always like to follow the manufacturer's specs and use the same horsepower.

2. Amperage

Amperage is a measure of how much current a motor draws. The more current a motor draws, the more power it uses.

When replacing an AC condenser fan motor, you need to match the amperage of the new motor to the old motor.

3. RPM

Revolutions per minute or RPM is a measure of how fast a motor is turning. The higher the RPM, the faster the motor spins.

When replacing an AC condenser fan motor, you need to match the speed of the new motor to the old motor.

The most common RPMs for AC condenser fan motors are 825 RPM and 1075 RPM.

4. Voltage

The voltage rating of a motor is how much voltage must be supplied to the motor to operate.

For example, a single-phase AC condenser fan motor might be rated at 208-230 volts. This means the motor can run on either 208 volts or 230 volts (240 volts is nominal in most regions).

When replacing the AC condenser fan motor, you need to use a supply voltage that matches the motor rating.

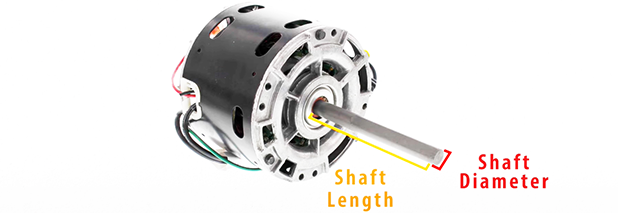

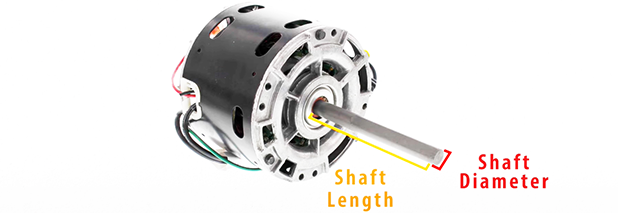

5. Shaft size

The shaft is a metal rod that sticks out from the motor. The purpose of the shaft is to transfer work from the motor to the motor's load.

Motor shafts are available in different diameters and lengths. Most AC condenser fan motors have a ½” shaft diameter.

If you replace the AC condenser fan motor with a replacement OEM motor, the length of the shaft will be the same size.

However, if you use an aftermarket replacement motor, the length of the shaft will be longer. The motor shaft is longer to accommodate different types of applications. This means you will need to cut the shaft of the aftermarket fan motor to the correct size.

Another thing you need to do is set the fan blades at the correct height. If you are using a full replacement OEM motor, you can set the fan blades in the same position on the motor shaft.

If you are using an aftermarket motor, you will need to take a height measurement to determine where the fan blades need to fit on the shaft of the new motor.

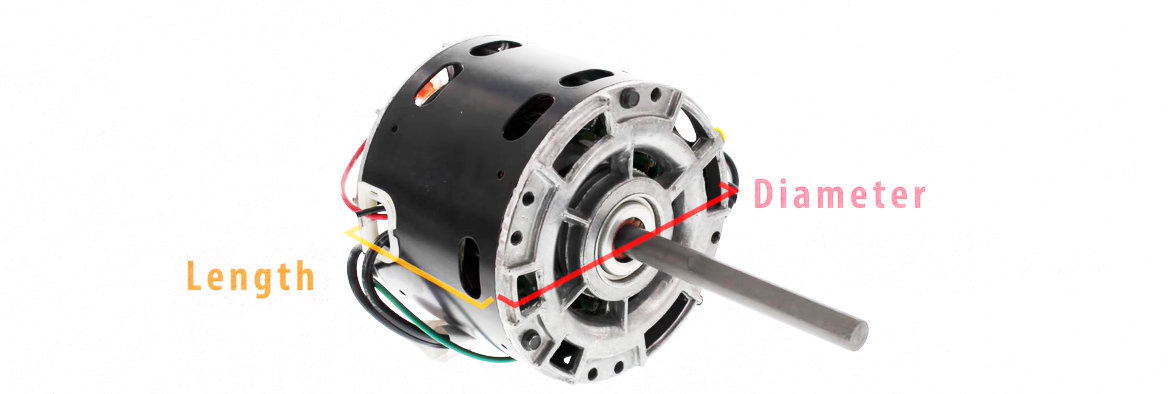

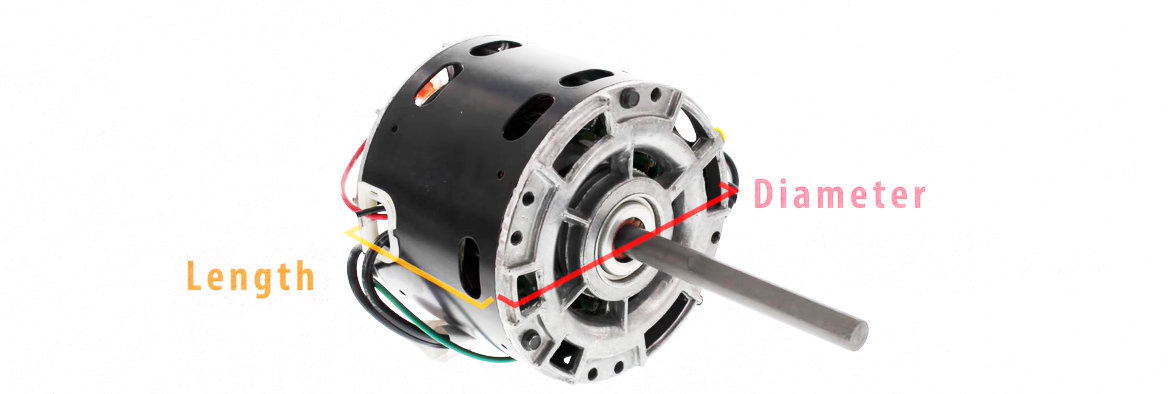

6. Frame Size

The frame of the motor is the housing that surrounds the motor. Motors for AC condenser fans come in several different sizes.

The most common frame size for residential AC condenser fan motors is a 48 frame. The 48 frames are 5-⅝” in diameter.

Some larger AC condensers may have a 56 frame fan motor. The 56 frame is 6-½” in diameter.

7. Speeds

Most homes have single-stage condensers, so you may only need a regular single-speed condenser fan motor.

However, some AC capacitors have multiple stages. If you have a multi-stage condenser, your condenser fan motor will have multiple speeds.

Most multi-stage condensers have 2 stages, so the condenser fan motor will have 2 speeds - low and high.

8. Direction of Rotation

The direction of rotation of the AC condenser fan is critical. If the fan motor is spinning the wrong way, your AC will not work.

How do you know which way your AC condenser fan should spin?

The easiest way to determine the direction of rotation of an AC condenser fan is to look at the fan blades. The fan blades should draw air from the top of the condenser.

The direction of motor rotation is usually expressed as either clockwise (CW) or counterclockwise (CCW). Most manufacturers indicate the direction of rotation when looking at the shaft end of the motor.

The easiest way to find out the shaft rotation is to look at the motor nameplate. There is usually an arrow on the nameplate indicating the direction of rotation of the motor.

Some motors are reversible. This means that you can change the direction of rotation of the motor.

Most reversible motors have external connectors that stick out of the motor. If you swap the connectors, the motor will change direction.

9. Capacitor Rating

Most AC condenser fan motors are Permanently Split Capacitor (PSC) motors. PSC motors require a capacitor to operate.

The motor will have the rating of the capacitors that need to be used. The capacitor rating will be stated on the motor nameplate. For example, a motor might require a 5µF/450V capacitor to operate.

The microfarad (µF or MF) rating of the capacitor needs to exactly match the marking on the motor. However, at least the voltage rating of the capacitors needs to be marked on the motor.